Industrial maintenance, industrial stripping

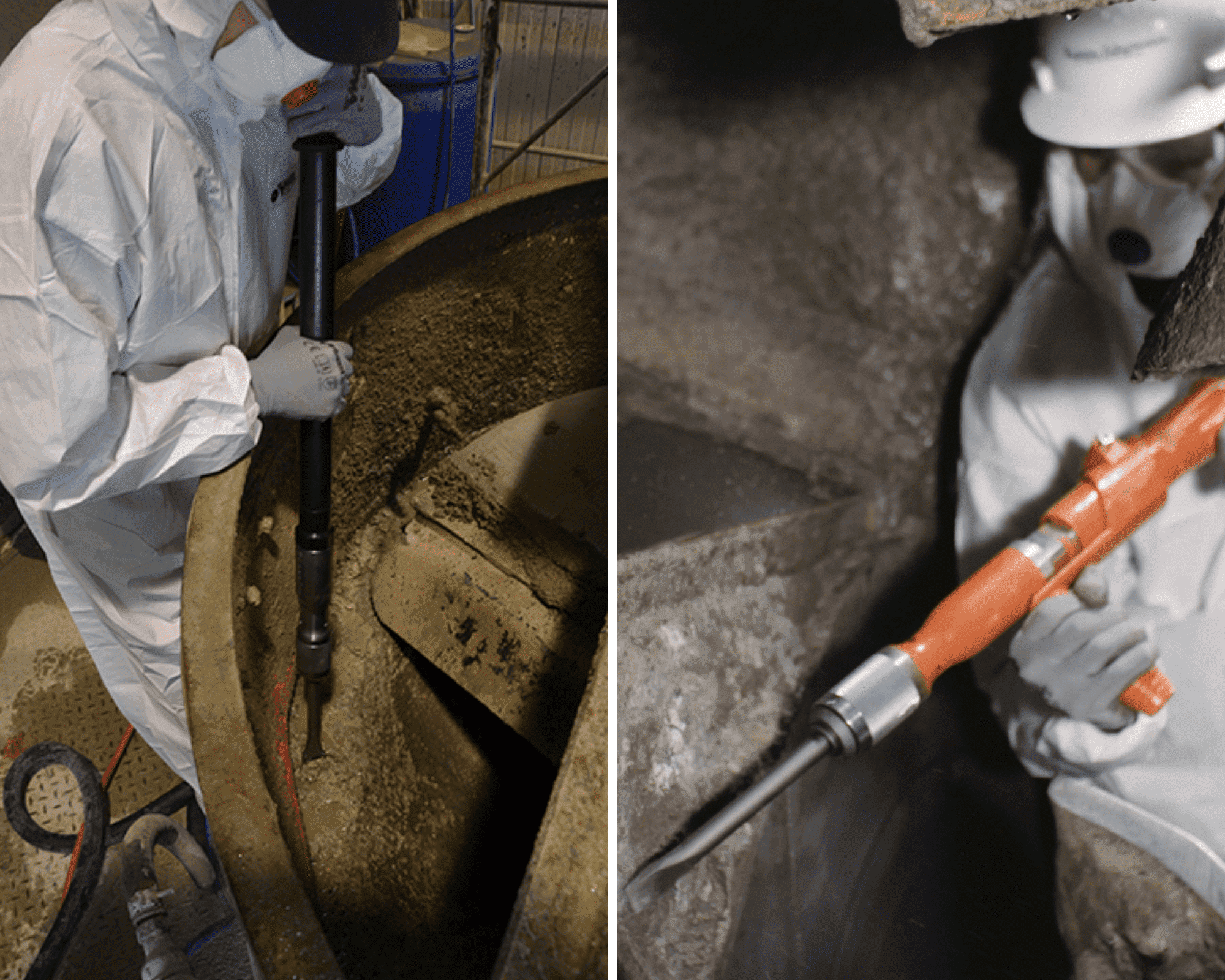

Industrial maintenance aims to renovate and maintain production equipment in good condition, without damaging it. This stripping technique is essential to maintain the refractory linings of industrial furnaces, converters and ladles used in foundries, the ducts and chimneys of industrial installations, and all components subject to fouling.

Regular maintenance ensures that industrial production tools remain in good condition and that production quality is maintained by limiting the risk of pollution of materials produced in ladles and furnaces in the steel, cement and glass industries. Many industrial sectors are also concerned: refineries, petrochemicals, chemicals, waste incineration, energy, cement works, etc.

How to maintain industrial production tools

In the industrial sector, maintaining production tools can be a laborious and time-consuming task. These activities are often repetitive, but they are of vital importance to the entire manufacturing process.

Some industrial installations require the use of maintenance equipment specially designed to meet the particular requirements of their environment, such as accessibility, confined spaces, humidity, heat and many others.

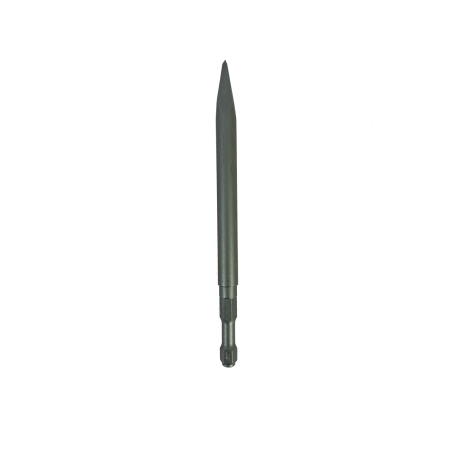

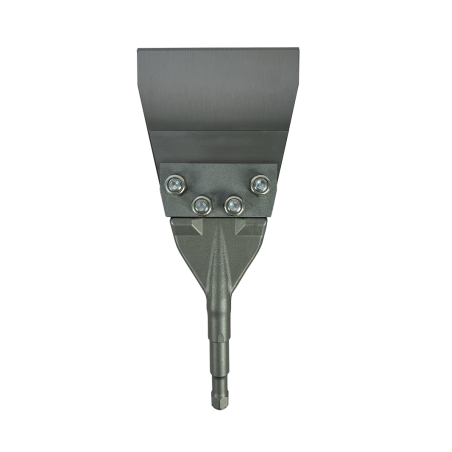

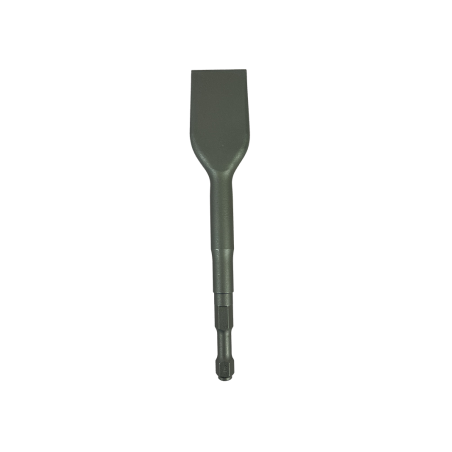

The Scrap'Air 38 pneumatic scraper is a versatile tool available in short-, medium- and long-handled versions. It's ideal for cleaning industrial tools such as mixers, concrete batching plants, conveyors and much more.

Thanks to its versatility, power and manoeuvrability, it is also used for a variety of masonry jobs, including light demolition of walls and floors, as well as stripping furnaces and ventilation ducts in mines.